Business

Business Amorphous Alloy Foils Div.

Amorphous Alloy Foils Div.

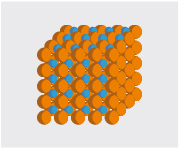

Difference in Array of Metal Atom

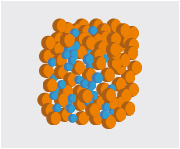

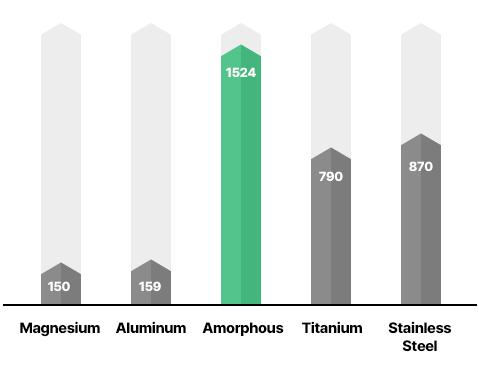

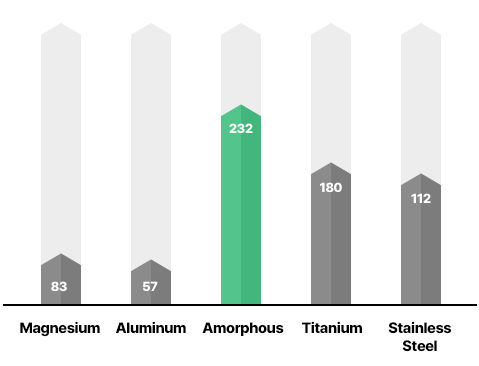

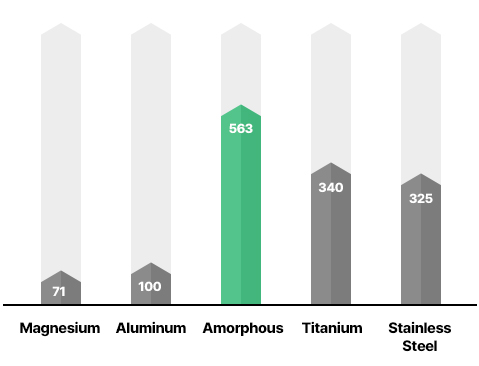

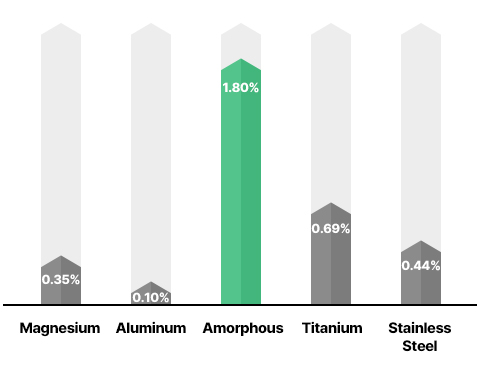

Typical strength and elastic limits for various materials

Zr-based, Ti-based, Ai-based,

Cu-based and so on.

30μm ~ 200μm

Max, 125 mm

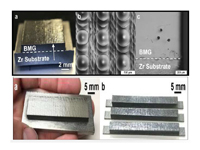

Inner Hinge for Flexible Display

Feedstock for Laser Foil Printing

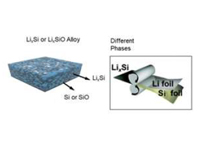

Amorphous Li-Si Foil

Hydrogen Separation Membrane Material

Flexible all-solid-state symmetric supercapacitor

High-Precision Flow Sensor with Semi-conductor

Electrostatic Chuck

Ceramic Substrate for EV